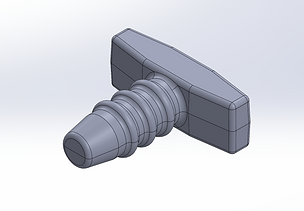

Screwdriver

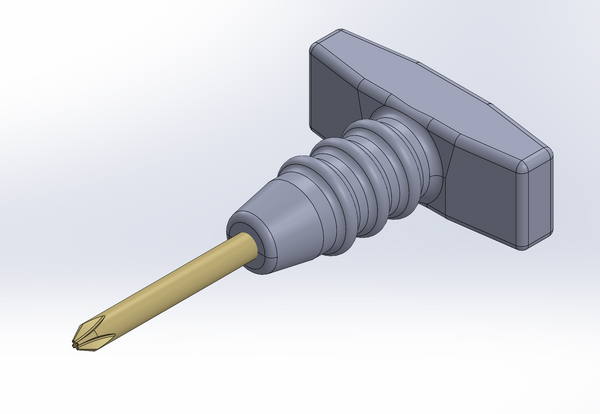

Task: Design an ergonomic pocket sized injection molded Vydyne 41 Black High Impact Nylon screwdriver handle with a Philips head 89 mm long core.

Objectives

-

Adhere to specified constraints (volume, dimensions, Wera PH#2 blade incorporation, over-molding)

-

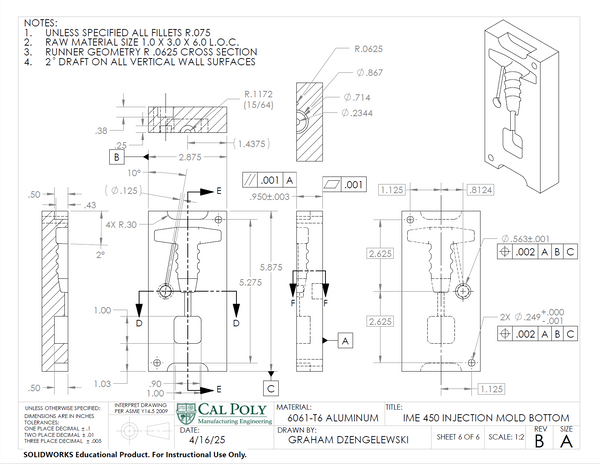

Develop a 6061-T6 Aluminum injection mold compatible with the Morgan injection Molding Press, applying Design for Manufacturability (DFM) principles.

-

Fabricate the mold tooling using HSMWorks for CAM programming and a Haas VF-2 CNC mill.

-

Produce functional prototypes via injection molding to validate the design and process

Design

The inspiration behind the design comes from a golf wrench tool, which is commonly used by golfers to adjust driver head and shaft combinations

Keys to Success:

-

Uniform wall thickness

-

Account for shrinkage as part cools

-

Incorporating ribs for strength,

-

Adding draft to all vertical walls for mold release

-

Avoiding undercuts

Manufacturing

I used an HSM to map and plan tool 3 axis paths and create a tooling library to machine the top and bottom mold halves.

Post processed to a Haas VF2 to create NC code and added a sub routine M98 P100 for probing the material to locate the G54 in the machine offsets.

NC files were saved onto a USB drive and inputted into the Haas VF2 for machining.

Final Product

I successfully achieved the core objectives of this project and produced an ergonomic over molded Phillips head screwdriver